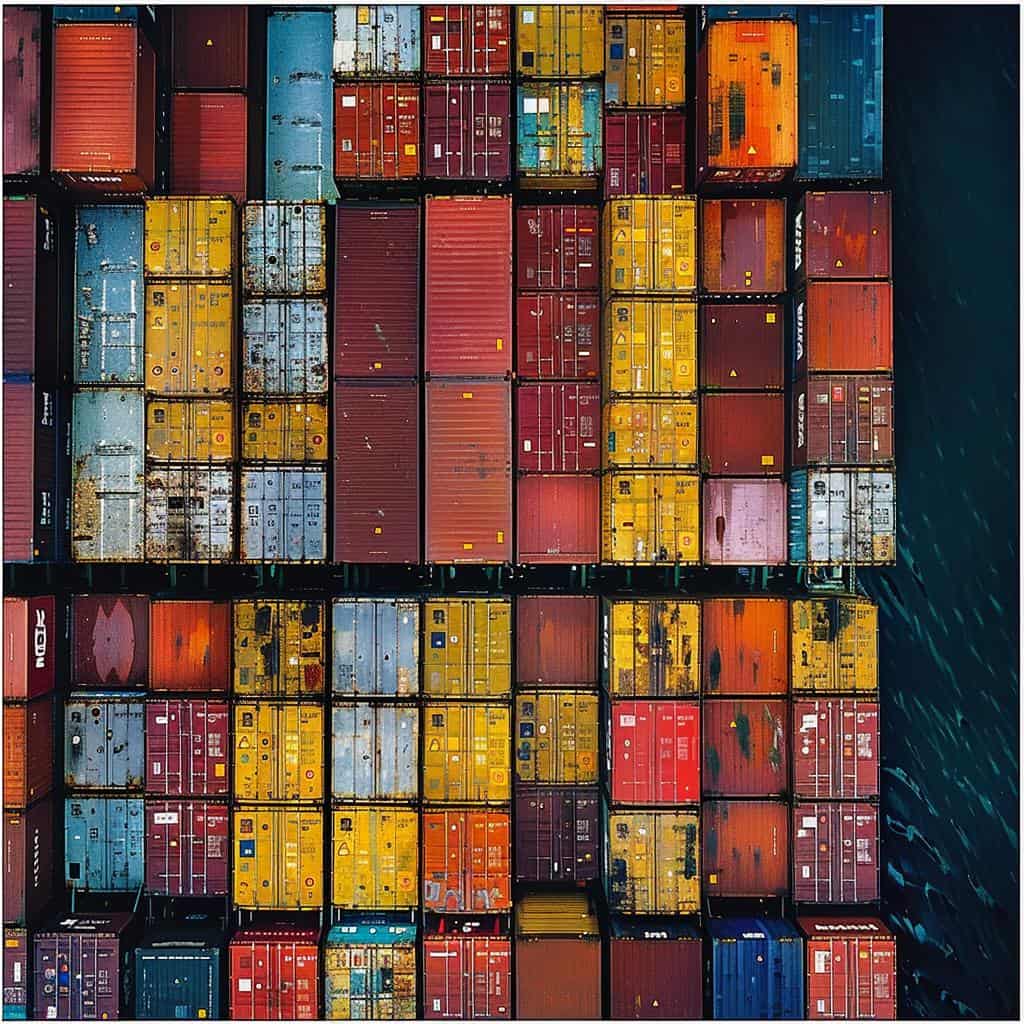

The components of a shipping container are typically made of steel. Both standard transport cargo containers and high cube containers are made from steel, providing strength and durability for the shipping process.

The dimensions of a standard steel shipping container are usually 20 feet long, 8 feet wide, and 8 feet 6 inches tall. On the other hand, high cube shipping containers have an additional foot in height, making them 9 feet 6 inches tall.

The structure of a shipping container includes the walls steel beams, roof, and floor, all made of corrugated steel panels. Other components include the doors, corner castings, and locking mechanisms, ensuring the safety and security of the goods being transported.

These components work together to make shipping containers an efficient and reliable method of transporting goods across the globe.

Storage Containers Capacity

When it comes to different types of shipping containers, such as high cube containers versus standard ones, the primary difference lies in their storage capacity. A standard shipping container is typically 8 feet 6 inches tall, while a high cube container adds an extra foot, making it 9 feet 6 inches tall.

This additional height allows for more storage space, making high cube containers ideal for transporting bulky or oversized cargo. However, it’s important to note that the increased height of cargo doors doesn’t affect the payload capacity of the container.

How Are Shipping Containers Constructed

Have you ever wondered how shipping containers are constructed?

The construction of modern shipping containers also involves a series of steps to ensure durability and efficiency.

The first step is building the floor space, which is made of steel cross-members and marine-grade plywood. This floor frame provides a sturdy foundation for the container and allows for easy transportation and stacking.

The walls and roof of the container are then added, typically made of corrugated steel panels. These panels are welded together to create a strong and secure structure for metal shipping containers.

The dimensions of standard shipping containers are 20 or 40 feet in length, 8 feet in width, and 8.5 feet in height. However, high cube shipping containers offer extra vertical space, with a height of 9.5 feet. This additional space inside the container is valuable for storage purposes, allowing the storage unit and for more efficient use of the container’s capacity.

Quality Control and Safety Standards in Shipping Container Construction

The construction of shipping containers is a process that demands meticulous attention to quality control and adherence to stringent safety standards. These measures are crucial to ensure that containers are capable of withstanding the rigors of international shipping, including extreme weather conditions, heavy loads, and long sea voyages.

Quality Control Measures

Material Inspection: The process begins with a thorough inspection of the raw materials, primarily Corten steel, used in shipping container design and construction. This steel is checked for its tensile strength, corrosion resistance, and overall quality to ensure it meets the required standards.

Design and Engineering Compliance: Each container design is scrutinized to comply with international standards such as ISO (International Organization for Standardization). This ensures that the containers are of a uniform size, making them stackable and easily transportable by various modes of transport.

Welding Inspection: Welding is a critical part of container construction. Automated and manual welding processes are closely monitored. Welds are inspected for their strength and integrity, often using non-destructive testing methods like ultrasonic testing.

Corrosion Protection: Containers are treated for corrosion resistance. This includes the application of protective paints and primers that shield the steel from rust and degradation, especially when exposed to salty sea air.

Flooring Installation: The installation of the shipping container floor, typically made from marine-grade plywood, is inspected for durability and resistance to wear and tear. The wood is also checked for any treatment with harmful chemicals.

Safety Standards

Load Testing: Containers undergo rigorous load testing to ensure they can handle the specified weight capacities. This includes both static and dynamic testing.

Weather Resistance Testing: To ensure steel shipping containers can withstand extreme weather, they are subjected to tests that simulate harsh environmental conditions like extreme cold, heat, and humidity.

Certification: Upon passing all inspections and tests, containers are certified by relevant authorities. This includes obtaining a CSC (Container Safety Convention) plate, which indicates that the container is fit for global shipping.

Regular Audits: Manufacturing facilities undergo regular audits to ensure ongoing compliance with quality and safety standards. These audits are conducted by internal teams or external certification bodies.

Worker Safety: Alongside container safety, worker safety during the construction process is paramount. This includes adherence to occupational health and safety guidelines, provision of protective gear, and training for handling heavy machinery and hazardous materials.

The construction of shipping containers involves a comprehensive system of quality control measures and safety standards. These protocols ensure that the containers not only meet the functional requirements of shipping but also uphold the safety of the cargo, the environment, and the individuals handling them throughout their lifecycle.

Environmental Considerations in Container Construction

In recent years, the shipping container manufacturing industry has increasingly focused on the environmental impact of container construction, recognizing the importance of sustainable practices. The primary material used in container construction, Corten steel, is known for its durability and recyclability, which contributes to environmental sustainability. However, the production of steel is energy-intensive and generates significant carbon emissions. To mitigate this, manufacturers are exploring the use of recycled steel and implementing more energy-efficient production methods.

Another critical aspect is the treatment of container floors, traditionally made from tropical hardwoods. The harvesting of these woods raises concerns about deforestation and biodiversity loss. In response, there is a growing shift towards using more sustainable materials like bamboo or recycled composite materials, which offer similar durability without the environmental toll of hardwood extraction.

The use of hazardous chemicals in paints and coatings for corrosion resistance is another environmental concern. The industry is moving towards the use of water-based, low-VOC (Volatile Organic Compounds) paints and advanced coating technologies that are less harmful to the environment and human health.

Furthermore, the end-of-life disposal of shipping containers poses significant environmental challenges. To address this, there is an increasing emphasis on the repurposing and recycling of old containers. Repurposing into structures like homes, offices, or community spaces extends the life of the containers and reduces waste. For containers that are no longer usable, recycling the steel and other materials minimizes the impact on landfills.

Frequently Asked Questions

What materials are used to make shipping containers?

Shipping containers are primarily made from maritime-grade corten steel, also known as ‘weathering steel’. Corten steel is an alloy, meaning it is a combination of steel and other metals. This material is specifically chosen for its durability and ability to withstand harsh weather conditions. Despite steel alloys being designed to rust, corten steel’s unique composition prevents deeper corrosion, making it an ideal material for shipping containers.

Are shipping containers rust proof?

Shipping containers are made from Corten steel, which is considered an ‘Atmospheric Corrosion Resistant Steel.’ This means that it is highly resistant to atmospheric weathering compared to other unalloyed steels. However, since Corten steel contains some iron, it is still prone to rust, albeit at a slower rate than regular steel.

Therefore, while steel shipping containers are not completely rust-proof, they are designed to be more resistant to rust and corrosion than many other types of steel. Regular maintenance and preventive measures can further protect them from rusting.

Are shipping containers hazardous?

Shipping containers can potentially be hazardous due to the presence of harmful chemicals. Some cargo in shipping containers may off-gas dangerous chemicals, such as toluene from product packaging and benzene from plastics, which can damage bone marrow and cause anemia.

Additionally, second-hand containers might have coatings with chemical components that are toxic to humans in certain quantities. There is also a risk of substances from previous cargo being left inside, lining the interior of the container. Therefore, while shipping containers themselves are not inherently hazardous, the materials they have transported or the chemicals used in their construction and maintenance can pose health risks.

What is the floor of a shipping container made out of?

The floor of a shipping container is typically made of marine-grade plywood or bamboo. “Marine grade” refers to the wood having more ply (19 ply or 21 ply) than traditional construction plywood, which results in a more stable floor that is less prone to warping.

Marine-grade plywood was specifically developed for use in shipbuilding due to its durability and resistance to harsh conditions, making it well-suited for the floors of most shipping containers. Additionally, some shipping containers may use bamboo flooring, which is known for its durability and resistance to moisture.

Conclusion

To wrap up, let’s summarize the key points discussed about the construction of shipping containers.

Shipping containers are made of steel, which makes them durable and able to withstand harsh environments. They’re cost effective, providing an affordable solution for storage and transportation needs.

The standard dimensions and weight of shipping containers allow for easy stacking and efficient shipment on trucks, trains, and ships.

The benefits of using shipping containers include their versatility, as they can be easily modified for various uses, and their security, as they’re lockable and protect goods from theft and damage.

The shipping container industry plays a vital role in global trade, meeting the requirements of businesses across different sectors.