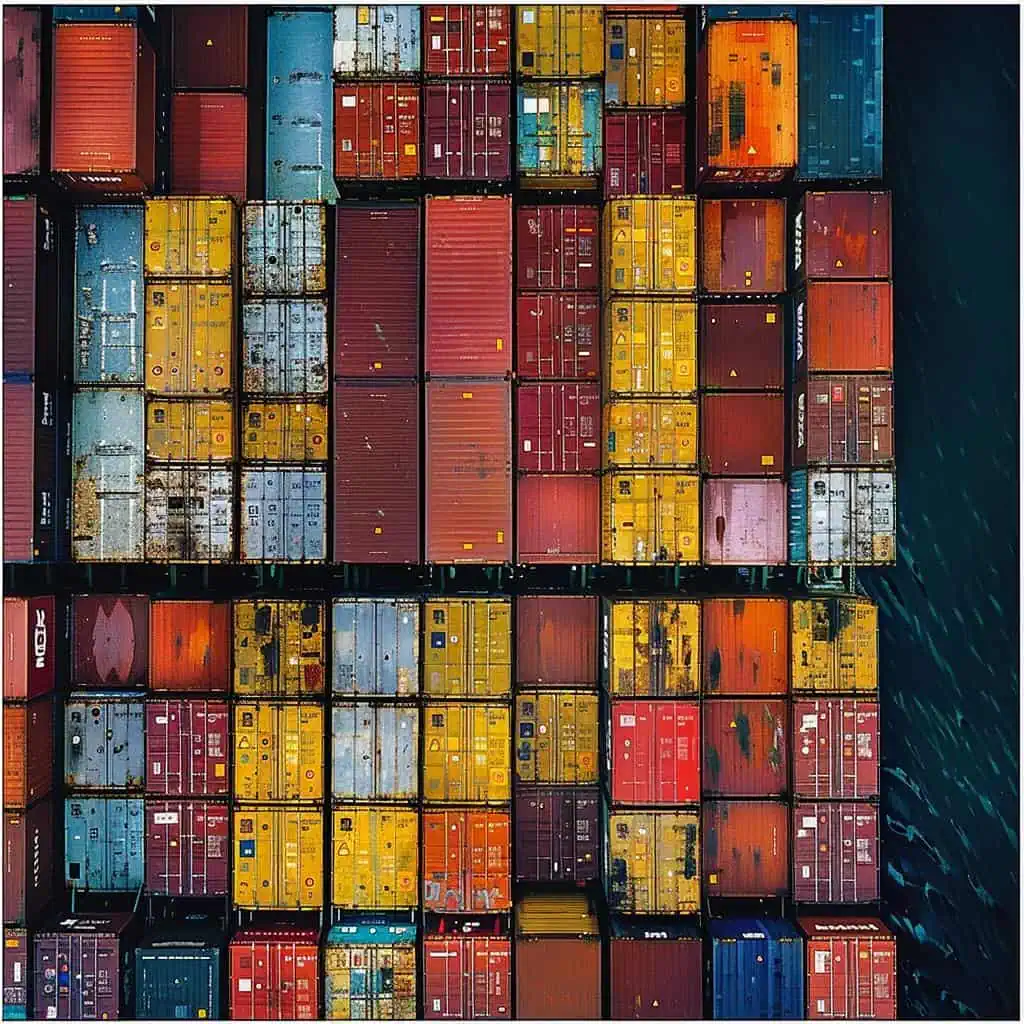

When it comes to understanding how to move a shipping container, several factors come into play. These robust, standardized boxes, designed for seamless transportation across various modes – be it by road, rail, or sea, present unique challenges when being relocated. Moving them, especially when loaded, demands meticulous planning, the right equipment, and strict adherence to safety protocols.

Preparation Before Moving

Before moving a shipping container, it’s not just about lifting and transporting. Proper preparation ensures that the whole container transportation process is smooth, safe, and efficient.

Know the Weight of Your Shipping Container(s)

The weight of a shipping container can vary significantly based on its size and contents. An empty 20-foot container typically weighs around 2,300 kg, but once loaded, it can weigh up to 28,200 kg. Knowing the exact weight of empty shipping containers is crucial as it affects the type of equipment you’ll need to transport shipping containers, its weight limit the transportation cost, and safety measures. Overloading an empty container can lead to equipment failure or even accidents.

Property-to-property Transport Considerations

Relocating a shipping or storage container from one location to another isn’t merely about moving a large object; it’s about ensuring that the move is safe, efficient, and in compliance with various regulations. Each step of the journey requires meticulous planning and access to the right resources.

Assess the Terrain:

- Ground Composition:

- Asphalt: This is a preferred surface for moving heavy objects as it provides stability. However, repeated movement of heavy containers can cause wear and tear over time.

- Gravel: A common ground type in many industrial areas. While it offers decent traction, it’s essential to ensure the gravel is compacted to prevent the container or transporting vehicle from sinking.

- Grass: The least stable of the three, moving a container on grass requires additional precautions. Plywood or metal sheets might be laid down to create a makeshift path, ensuring the weight is distributed and preventing ruts or damage to the lawn.

- Gradient and Elevation:

- Incline Challenges: Even a slight incline can make moving a container significantly more challenging. Gravity can cause the container to roll, making manual adjustments difficult.

- Equipment Adjustments: On slopes, brake adjustments or wheel chocks might be used to prevent unwanted movement. Additionally, winches or tugs can assist in pulling or holding the container in place.

- Manpower: Sometimes, the best solution is human intervention. Having extra hands on deck can help guide the container, especially when navigating tight or tricky spots.

Check for Overhead Obstructions:

- Height Assessments:

- Container Dimensions: Standard shipping containers come in various heights, with the most common being 8.5 feet (standard) and 9.5 feet (high cube). When loaded onto a truck or dolly, the total height increases, making it crucial to have an accurate measurement.

- Vehicle Additions: The height of the transporting vehicle, especially if it’s a tilt bed truck or a flatbed trailer, adds to the total elevation. This combined height should be compared against any potential overhead obstructions.

- Temporary Structures:

- Scaffolding: Common in construction zones, scaffolding can vary in height. Ensure there’s enough clearance, and always be cautious as scaffolding can be less stable than permanent structures.

- Event Tents or Canopies: In urban areas or during events, temporary tents might be set up. While they’re usually not as high as other obstructions, their ropes or supports can still pose challenges.

- Signage and Banners: Temporary signs or banners, especially those hung across roads or driveways, should also be considered. While they might not damage the container, the container can easily tear or bring them down.

Plan the Route:

Navigating the path for moving a shipping container is akin to charting a course for a ship. Every potential obstacle, legal requirement, customs clearance, and logistical challenge must be anticipated and planned for.

- Local Authorities:

- Permit Requirements: Some municipalities or states have strict regulations about transporting oversized loads. This might involve obtaining a special permit, especially if the container will be moved during peak traffic hours or through densely populated areas.

- Escort Vehicles: In certain situations, local regulations might require the use of escort vehicles, especially for larger containers or when moving through busy roads. These vehicles help in guiding the transporting vehicle and ensuring the safety of other road users.

- Scout Ahead:

- Road Width and Quality: Not all roads are built the same. While highways and main roads are designed to handle heavy loads, smaller roads, especially in older parts of towns or in rural areas, might not be. They could have weight restrictions or might be too narrow.

- Potential Hazards: Things like construction zones, road closures, or events can disrupt a planned route. Knowing these in advance can save time and reduce the risk of damage.

- Bridge and Tunnel Clearances: Especially in older cities, some bridges or tunnels might not be high or wide enough to accommodate a container on a transporting vehicle.

Specialized Container Movement Techniques

As the demand for shipping containers has grown, so too have the methods and technologies for moving them. Each technique and method is designed with specific scenarios in mind, ensuring efficiency and safety.

Property-to-property Transport With Large Vehicles and Trailers

These aren’t just any vehicles; they’re specially designed and equipped to handle all the weight and unique challenges presented by shipping containers and container transport.

- Hydraulic Systems:

- Lift and Tilt: Modern hydraulic systems aren’t just about lifting. They can tilt a container at various angles, making it easier to load or unload in places with limited space.

- Speed Control: Advanced systems allow operators to control the speed of the lift or tilt, ensuring the container is handled smoothly, reducing the risk of damage to the contents.

- Locking Mechanisms:

- Electronic vs. Manual: While traditional twist locks require manual effort to secure, newer electronic locks can be engaged with the push of a button, ensuring a tighter and more secure fit.

- Redundancy: Some transporting vehicles come equipped with multiple locking mechanisms. This redundancy ensures that even if one lock fails, others can still hold the container in place.

- Maintenance: Just like any other part of the vehicle, locks need regular maintenance. This includes cleaning, lubrication, and checking for signs of wear and tear.

Dolly Specifics

Dollies might seem like a simple piece of equipment, but their design and functionality are the results of careful engineering. They bridge the gap between large transport vehicles and manual labor, offering a solution that’s both efficient and versatile.

Different Types of Container Dollies and Their Applications

The world of container dollies is diverse, with each type tailored for specific scenarios and challenges:

- Four-wheel Dollies:

- Compact Design: Their relatively small footprint makes them a favorite for locations where space is a premium. Whether it’s navigating between closely parked vehicles or moving through narrow alleyways, their design shines.

- Quick Turns: The four-wheel configuration allows for sharp turns, which is especially useful in congested areas or when precise positioning of the container is required.

- Strength in Size: Don’t let their size fool you. With robust construction and the right materials, these dollies can handle containers filled to capacity without breaking a sweat.

- Multi-wheel Dollies:

- Balanced Load: More wheels mean a better distribution of the container’s weight. This design minimizes the stress on any single wheel, ensuring a smoother move.

- Adaptive Movement: Whether it’s moving over a bumpy construction site or gliding across a warehouse floor, multi-wheel dollies adapt to the terrain. Their flexibility reduces the risk of the container jostling or contents shifting.

- Safety First: The broader base of multi-wheel dollies offers enhanced stability, especially when moving taller containers that have a higher center of gravity.

Dolly Wheels: Sizes, Types, and Importance

Wheels are to delivery truck, trailer bed or a dolly what legs are to a human. They determine where it can go, how fast it can move, and how much total weight that it can bear:

- Size Matters:

- Large Wheels: Ideal for rough or uneven terrains, they can roll over obstacles with ease. Their increased diameter allows for faster movement over longer distances.

- Small Wheels: Perfect for precision tasks. They offer tighter control, especially when positioning a container in a specific spot.

- Types of Wheels:

- Pneumatic Wheels: Air-filled and cushiony, they act as shock absorbers. They’re perfect for terrains with lots of bumps or when the container contents are fragile.

- Solid Wheels: Made from solid rubber or plastic, they’re durable and can withstand sharp objects, chemicals, or heavy loads. Their low-maintenance nature makes them a favorite for many industrial applications.

Alternatives to Traditional Movement Methods

In the dynamic world of container logistics, adaptability is key. While the tried-and-true methods to transport containers have their place, there are times when unconventional approaches are not just beneficial but necessary. These alternative delivery methods offer solutions tailored to specific challenges, ensuring that containers reach their destination safely and efficiently, regardless of the obstacles.

Alternatives to Dollies: Forklifts, Cranes, Trucks, and Trailers

Each of these alternatives brings its own set of costs and advantages, tailored for specific scenarios:

- Forklifts:

- Versatility in Movement: Forklifts can move forwards, backwards, and side-to-side, offering unparalleled maneuverability in tight spaces.

- Stacking Ability: One of the primary advantages of forklifts is their ability to stack containers, making them invaluable in storage yards or warehouses.

- Weight Considerations: While forklifts are powerful, they have their limits. It’s crucial to match the forklift’s capacity with the container’s weight. Overloading can lead to equipment damage and safety hazards.

- Attachments: Modern forklifts can be equipped with various attachments, like extended forks or clamps, to handle containers of different sizes and shapes.

- Cranes:

- Vertical Mastery: Cranes excel in vertical movement. Whether it’s loading a container onto a towering cargo ship or placing it on a high-rise construction site, cranes rise to the occasion.

- Safety and Precision: Operating a crane requires a combination of skill and technology. Advanced cranes come with computerized systems that aid operators in making precise movements, ensuring the container is placed exactly where it needs to be.

- Space Efficiency: In congested ports or construction sites, ground space is a premium. Cranes, with their ability to lift containers over obstacles, can significantly optimize space usage.

- Training: Crane operation is a specialized skill. Operators undergo rigorous training and often need certifications, ensuring they can handle the equipment safely and efficiently.

-

FAQs:

- How do you lift a 40-foot shipping container? Liftinga 40-foot container requires heavy machinery like cranes or specialized forklifts. Ensure the equipment can handle the container’s weight.

- How do you safely move a shipping container? Use the right equipment, secure the container properly, and follow safety protocols. Ensure the route is free of obstacles and adhere to local regulations.

- How do you move a 20ft shipping container? A 20ft container can be moved using dollies, forklifts, or trucks. The choice depends on the distance and terrain.

- How do you move a shipping container without a forklift? You can use dollies, tilt bed trucks, or cranes, depending on the situation and distance.

Valtran’s Shipping Container Moving Service

Valtran, a renowned name in the container industry, offers specialized shipping container moving services tailored to meet diverse needs. Leveraging state-of-the-art equipment and a team of trained professionals, Valtran ensures the safe and efficient relocation of your shipping containers, whether it’s a short move within a facility or a longer haul across states. With a commitment to safety, punctuality, and customer satisfaction, Valtran stands out as a reliable partner for all your container moving needs.

Conclusion:

Navigating the complexities of how to move a shipping container requires a blend of careful planning, the right equipment, and a deep understanding of safety protocols. Whether you’re using dollies, forklifts, cranes, or specialized vehicles, the goal remains the same: to ensure the container reaches its destination securely and efficiently. As the demand for containerized transport grows, so does the importance of mastering the art of moving these robust units. And for those who prefer a hassle-free experience, companies like Valtran offer specialized services to handle the task professionally. In the end, whether you’re doing it yourself or hiring experts, the key to move your shipping container is to prioritize safety and efficiency in every step of the process.